Our Products

- General Purpose Belts

- Special Purpose Belts

- Pipe Conveyor Belt

- Steep Angle Conveyor Belt

- Grade SAR

- Grade M 24

- Grade N 17

- Grade SHR

- Grade UHR 200

- Grade CMR

- Grade OR

- Grade FR

- Grade HYGIENIC

- Chevron Type Belts

- Roll Series Conveyor Belting(Jointless Belting)

- Reel Conveyor Belting(Jointless belting)Reel Conveyor

- Belts With Sidewall

- Checared Belt

- Hygienic Belting

- Belt With Centre Cleats

- All Cotton Drytop Surface

- Rough Top/Grip Face

Pipe Conveyor Belts

Conveyor Belts designed to handle ecologically dangerous materials that cause severe pollution to the enviroment and working area. Suitable to handle :- Iron Ore

- Lime powder

- Cement powder & clinkers

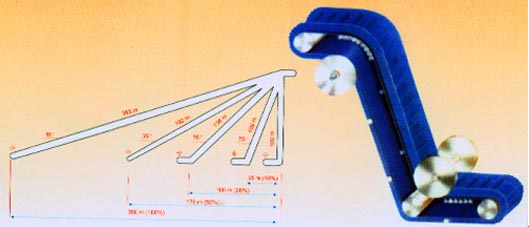

- Hazardouse chemicals Pipe Conveyor Belts have revolutioned the traditional mode of material handling. The belt in this system flattens itself at the loading and discharge stages after it assumes a pipe shape during its forward/return runs. The idlers are arranged in a hexagonal array with three rolls on either side.

Advantages :

It protects the material against rain, dust, wind, temperature, etc.It eliminates spilling and wastage.

It omits transfer points.

It has two dimension as well as Three dimension curves.

It eliminates canopy on the top of the structure.

It inclines the Conveyor upto 35".

It is enviormental friendly , especially against pollution hazard.

The Pipe Conveyor Belt can convey materials like coal / lignite, sinter, iron,pellets, coke, cement, limestone, clinker, ashes, grains and chemicals

These belts are cost effective, low labour and operating costs make it a very attractive mode of transportation.

Steep Angle Conveyor Belts

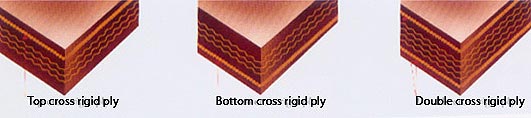

Steep Angle Conveyor Belts are modern age Bucket Elevator Box Belts. These Belts are made with Cleats and Sidewall. The concept of steep angle betls is to carry materials on steepest angle upto 90 degree with zero spillage These belts can be driven at the speed upto 5 M/sec. The space requirement is quite less as compared to Conventional Belts. Base Belts:Base Belt plays a key role in steep angle Conveyor Belts, The base belts are made with special cross rigid Member design to get more stability and rigidity. The different design of cross rigid belts are available with us as Indus `CTR`, Indus `CBR`, Indus `CDR`.(Please call us to know more details).

Side Wall : The side wall has been designed to achieve adequate rigidity to avoid the buckling under compression experienced by it at the point of deflection. The top portion of the side wall has been designed aganist tear & gauging resistant by using special rubber compound having high elongation at break. The side wall are fully reinforced with Synthetic fabric to get better life.

| Range of Sidewall | ||

| HEIGHT | BOTTOM WIDTH mm | WEIGHT PER MTR/KG |

| 40 | 50 | 0.500 |

| 60 | 50 | 1.4 |

| 80 | 50 | 1.9 |

| 100 | 50 | 2.0 |

| 120 | 50 | 2.5 |

| 120 | 75 | 3.5 |

| 160 | 75 | 4.5 |

| 200 | 75 | 5.4 |

| 240 | 75 | 6.5 |

| TYPE "T" | BASE WIDTH mm | SUITABLE HT. OF SIDE WALL mm |

| T 35 | 80 | 40 |

| T 55 | 80 | 60 |

| T 75 | 80 | 80 |

| T 90 | 110 | 110 |

| T 110 | 110 | 120 |

| T 140 | 150 | 160 |

| T 180 | 150 | 200 |

| T 200 | 150 | 200 |

| TYPE "K" | BASE WIDTH mm | SUITABLE HT. OF SIDE WALL mm |

| K 75 | 75 | 90 |

| K 90 | 110 | 110 |

| K 110 | 110 | 120 |

| K 140 | 150 | 160 |

| K 180 | 150 | 180 |

| TYPE "TKS" | BASE WIDTH mm | SUITABLE HT. OF SIDE WALL mm |

| TKS 75 | 75 | 90 |

| TKS 90 | 110 | 110 |

| TKS 110 | 110 | 120 |

| TKS 140 | 150 | 160 |

| TKS 180 | 150 | 200 |